Hardware

Hardware Overview

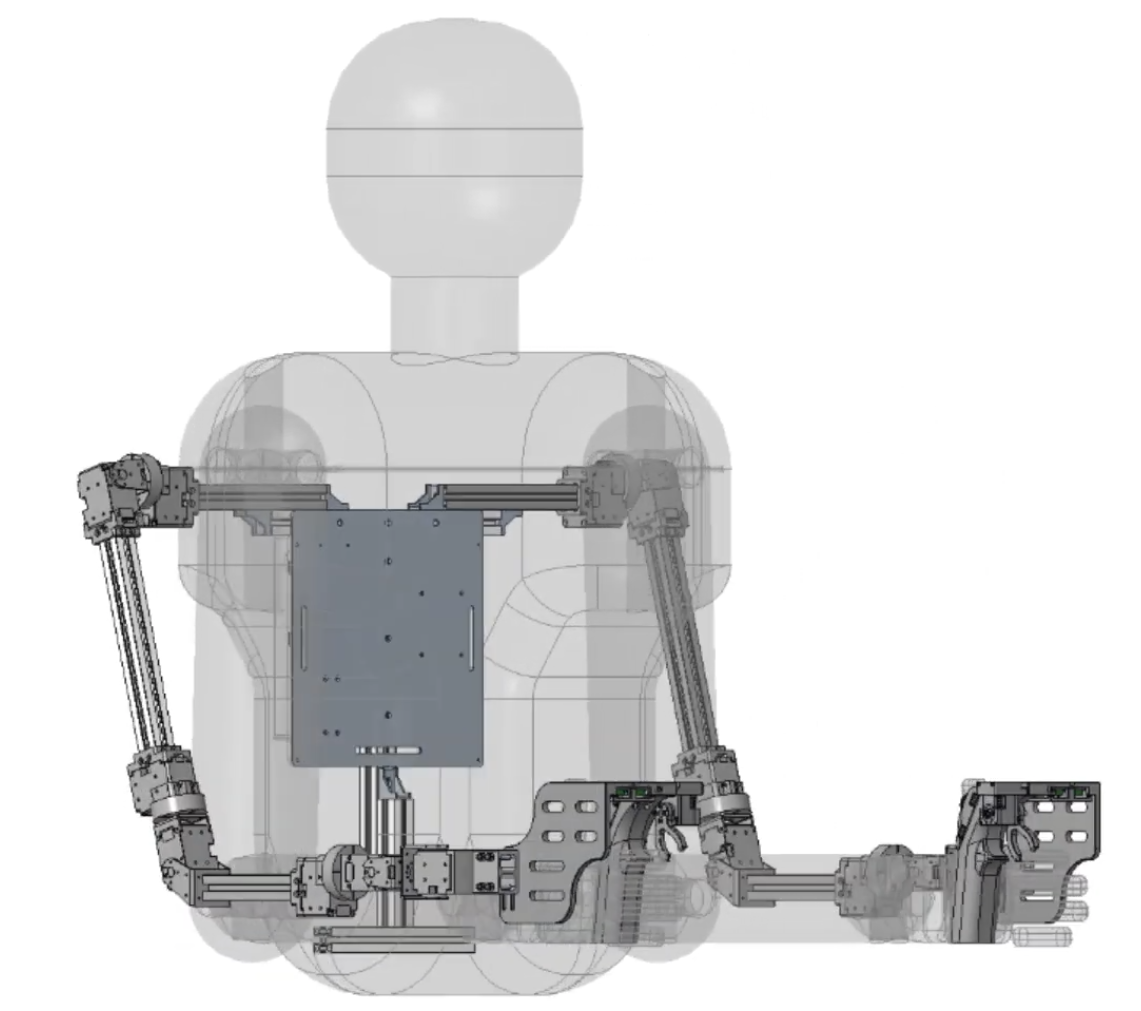

The AI Worker hardware platform combines advanced robotics with AI-powered capabilities to create a versatile semi-humanoid robot. Built around ROBOTIS DYNAMIXEL actuators, it features a mobile base with swerve drive, dual 7-DOF arms with dexterous hand/grippers, and a sensor suite that includes RGBD cameras and LiDARs. The system is powered by an NVIDIA Jetson AGX Orin computer to handle complex computations and AI tasks. The robot is designed for industrial applications, capable of performing tasks such as assembly, inspection, and logistics in dynamic environments. This comprehensive hardware design enables the AI Worker to perform complex manipulation tasks through imitation learning and reinforcement learning in various industrial environments.

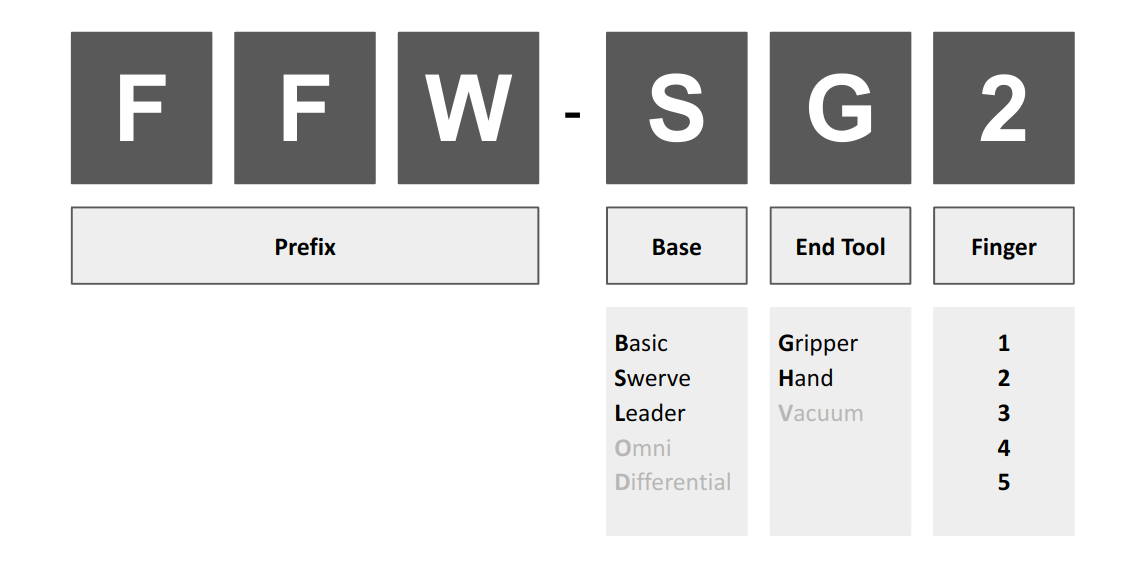

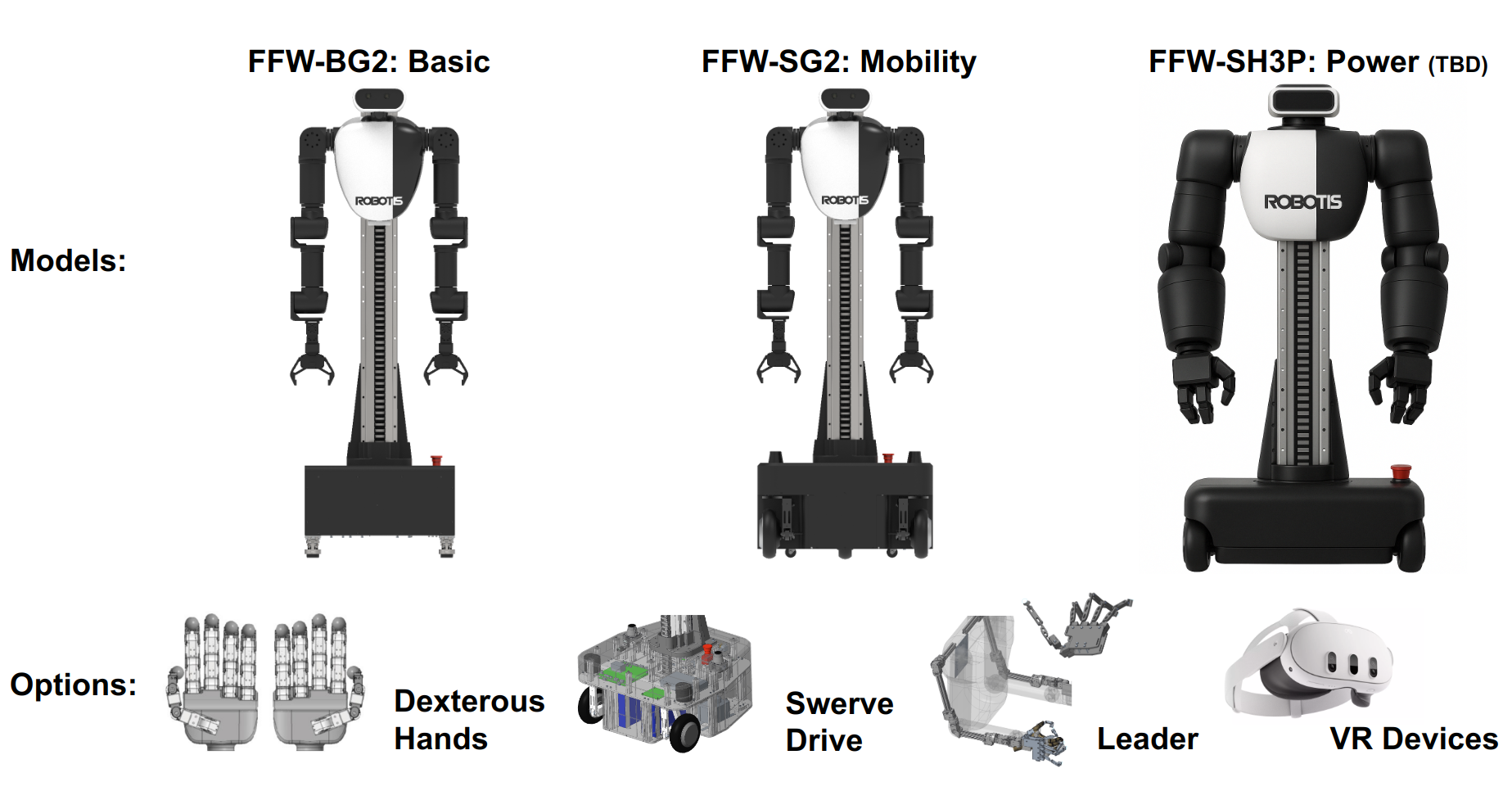

Product Models

Follower Specification

INFO

The FFW-BG2 model is scheduled for release in July 2025, while the FFW-SG2 model is expected to be released in September 2025. Please note that the specifications provided below are preliminary and subject to change before the official product launch.

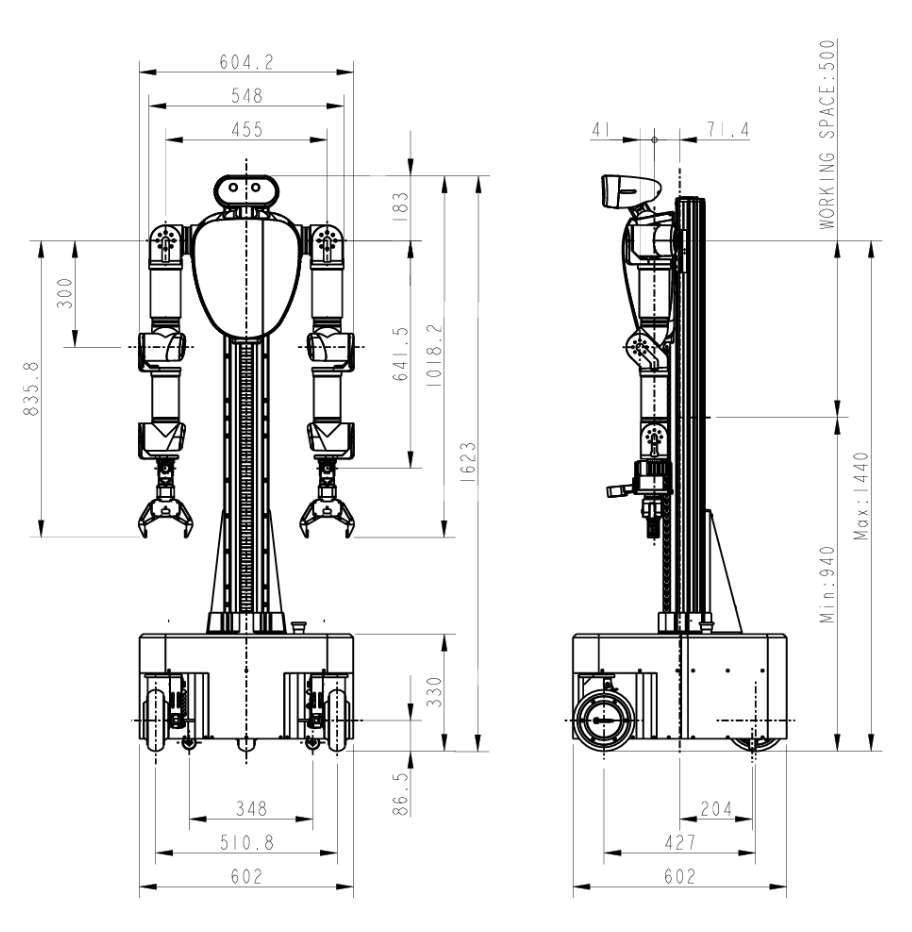

| Properties | Specification (FFW-SG2) | Specification (FFW-BG2) |

|---|---|---|

| Dimensions (WxDxH) | 604x602x1,623 (mm) 23.8x23.7x63.8 (inch) | 604x564x1,607 (mm) 23.8x22.2x63.2 (inch) |

| Weight | 90 kg (198 lb) | 85 kg (187 lb) |

| Actuator | Arm Joint 1~6: DYNAMIXEL-Y Arm Joint 7: DYNAMIXEL-P Head: DYNAMIXEL-X Lift: DYNAMIXEL-Y (see DYNAMIXEL Details) | Arm Joint 1~6: DYNAMIXEL-Y Arm Joint 7: DYNAMIXEL-P Head: DYNAMIXEL-X Lift: DYNAMIXEL-Y (see DYNAMIXEL Details) |

| Degrees of Freedom | - Total: 25 DOF - Arm: 7 DOF x 2 - Gripper: 1 DOF x 2 - Head: 2 DOF x 1 - Lift: 1 DOF x 1 - Mobile: 6 DOF | - Total: 19 DOF - Arm: 7 DOF x 2 - Gripper: 1 DOF x 2 - Head: 2 DOF x 1 - Lift: 1 DOF x 1 |

| Arm Reach | 641 mm (to wrist) + hand | 641 mm (to wrist) + hand |

| Arm Payload (Nominal) | 3.0 kg (single arm) 6.0 kg (dual arm)¹ | 3.0 kg (single arm) 6.0 kg (dual arm)¹ |

| Arm Payload (Peak) | 5.0 kg (single arm) 10.0 kg (dual arm)¹ | 5.0 kg (single arm) 10.0 kg (dual arm)¹ |

| Joint Resolution | -π(rad)~π(rad) -262,144~262,144 (pulse/rev) | -π(rad)~π(rad) -262,144~262,144 (pulse/rev) |

| Joint Range | (see Joint Configuration) | (see Joint Configuration) |

| Gripper/Hand | Standard: RH-P12-RN (see Gripper Specification) (Dexterous Finger Actuator in development, see Finger Actuator Specification) | Standard: RH-P12-RN (see Gripper Specification) (Dexterous Finger Actuator in development, see Finger Actuator Specification) |

| Mobile Type | Swerve Drive | None |

| Mobile Operation Velocity | 1.5 m/s | None |

| Power | Battery: 25V, 80Ah (2,040Wh) | AC powered via SMPS: 24VDC, 80A, 1,920W |

| Ambient Operating Temperature | 0 ~ 40℃ | 0 ~ 40℃ |

| Exterior Materials | Aluminum, Plastic | Aluminum, Plastic |

| Sensor | RGBD Camera x 3, LiDAR x 2, IMU (see Camera Specification) | RGBD Camera x 3 (see Camera Specification) |

| Host Interface | Ethernet (Wi-Fi router up to 1Gbps) | Ethernet (Direct connection to host PC) |

| Internal Communications | RS-485 | RS-485 |

| Communication Baudrate | 4 Mbps | 4 Mbps |

| Computer | NVIDIA Jetson AGX Orin 32GB | NVIDIA Jetson AGX Orin 32GB |

| Software | ROS 2 Support, Python, C++, Web UI | ROS 2 Support, Python, C++, Web UI |

¹ Peak payload capacity may vary depending on the robot's posture and motion profile.

Leader Specification

FFW-LG2 Model

FFW-LH5 Model

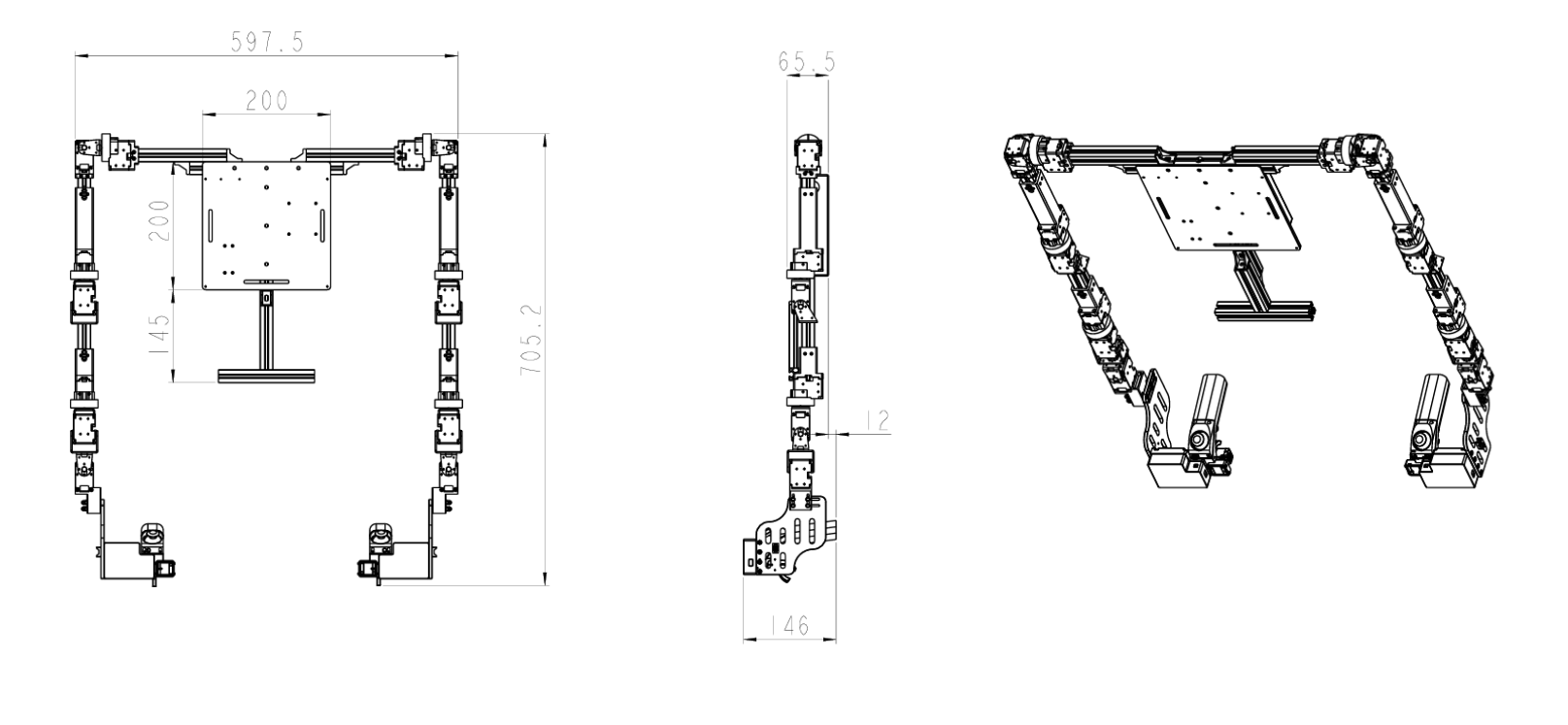

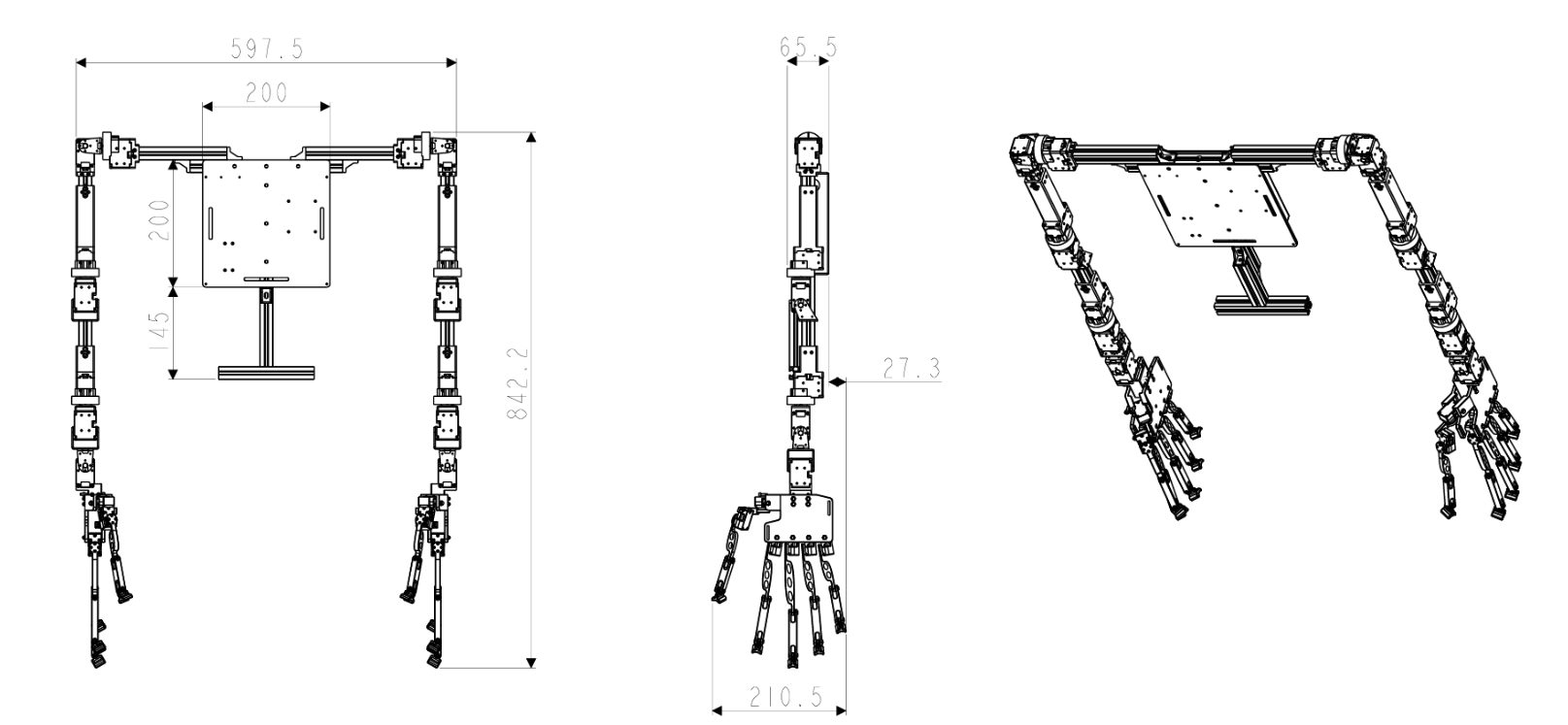

| Properties | Specification (FFW-LG2) | Specification (FFW-LH5) |

|---|---|---|

| Dimensions (WxDxH) | 598x146x705 (mm) 23.5x5.7x27.8 (inch) | 597x211x842 (mm) 23.5x8.3x33.2 (inch) |

| Weight | 3 kg (6.6 lb) | 3 kg (6.6 lb) |

| Actuator | Joint 1~7: DYNAMIXEL-X | Joint 1~7: DYNAMIXEL-X |

| Degrees of Freedom | - Total: 22 DOF - Arm: 7 DOF x 2 - Gripper: 1 DOF x 2 - JoyStick: 3 DOF x 2 | - Total: 60 DOF - Arm: 7 DOF x 2 - Hand: 20 DOF x 2 - JoyStick: 3 DOF x 2 |

| Exterior Materials | Aluminum, Plastic | Aluminum, Plastic |

| Internal Communications | RS-485 | RS-485 |

| Communication Baudrate | 4 Mbps | 4 Mbps |

| Software | ROS 2 Support, Python, C++ | ROS 2 Support, Python, C++ |

Camera Specification

The AI Worker utilizes a multi-camera system for robust perception and manipulation capabilities.

Head Camera: Stereolabs ZED Mini

A ZED Mini camera is mounted on the head for wide-area environmental understanding and navigation.

| Feature | Specification |

|---|---|

| Model Name | Stereolabs ZED Mini |

| Type | Stereoscopic RGBD with 6DoF IMU |

| Key Use | Wide-angle depth perception, SLAM, obstacle avoidance |

| Field of View | 102°(H) x 57°(V) |

| Max Resolution | 2208 x 1242 |

| Depth Range | 0.1m to 9m (3.9inch to 354.3inch) |

| More Information | Stereolabs ZED Mini Details |

Hand Cameras: Intel RealSense D405 (x2)

Two Intel RealSense D405 cameras are integrated into the robot's hands/grippers, providing precise, short-range depth data for manipulation tasks.

| Feature | Specification |

|---|---|

| Model Name | Intel RealSense D405 |

| Type | Stereoscopic RGBD |

| Key Use | Close-range depth sensing for grasping & manipulation |

| Field of View | 87°(H) × 58°(V) |

| Max Resolution | 1280 x 720 |

| Depth Range | 7cm to 50cm (2.7inch to 19.6inch) |

| More Information | Intel RealSense D405 Details |

Gripper Specification

The RH-P12-RN is a multi-functional, 1-DOF two-fingered robot hand. It features an adaptive gripping design with passive joints, allowing it to grasp objects of various shapes. The hand utilizes a 10W DC motor and offers torque control and current-based position control, enabling it to handle objects made of different materials. Key features of the RH-P12-RN include its lightweight design (500g) and high payload capacity (5kg). It also has detachable fingertips that can be easily replaced with customized ones. The RH-P12-RN is designed for easy integration with the AI Worker platform, making it suitable for various applications in industrial environments.

The RH-P12-RN is a multi-functional, 1-DOF two-fingered robot hand. It features an adaptive gripping design with passive joints, allowing it to grasp objects of various shapes. The hand utilizes a 10W DC motor and offers torque control and current-based position control, enabling it to handle objects made of different materials. Key features of the RH-P12-RN include its lightweight design (500g) and high payload capacity (5kg). It also has detachable fingertips that can be easily replaced with customized ones. The RH-P12-RN is designed for easy integration with the AI Worker platform, making it suitable for various applications in industrial environments.

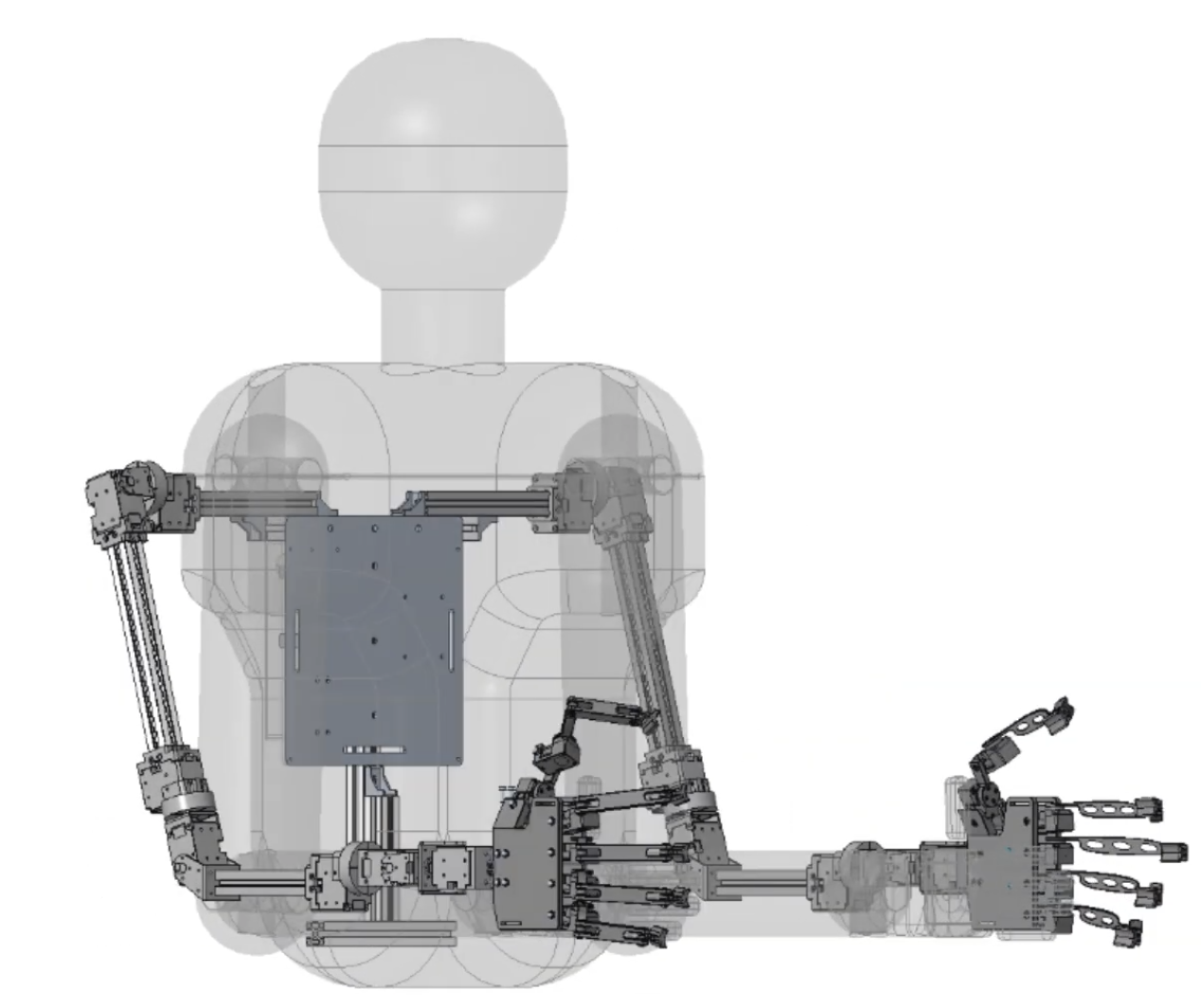

Finger Actuator Specification

Advanced finger actuators for the AI Worker are currently under development. These finger actuators are designed for complex manipulation tasks requiring human-like dexterity. Detailed specifications and options will be published in the near future once development is completed. Please contact us for more information about the availability of upcoming dexterous finger actuators.

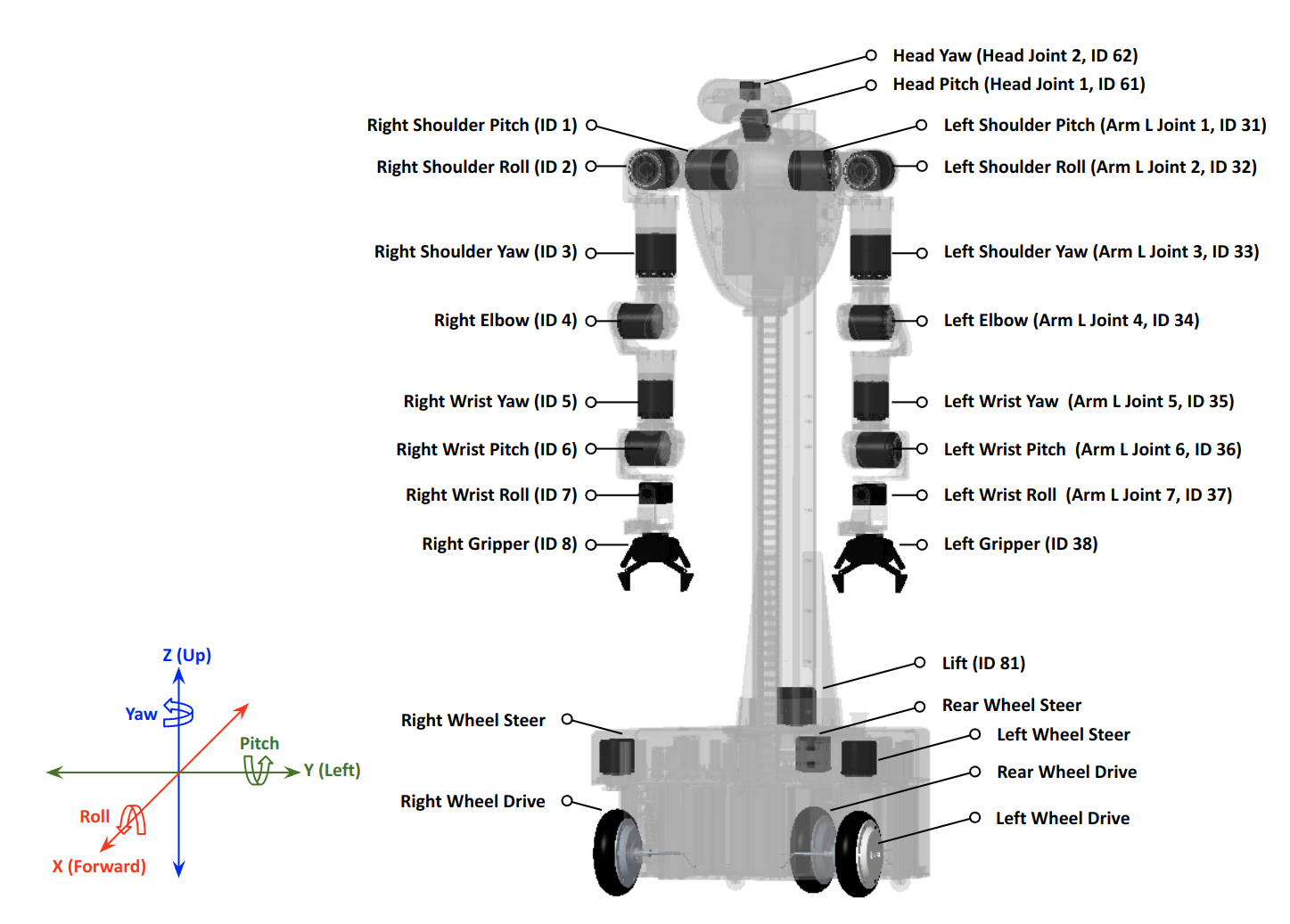

Joint Configuration and Nomenclature

| ID | Joint Name | Technical Name | Range |

|---|---|---|---|

| 1 | Right Shoulder Pitch | arm_r_joint1 | -180° ~ 180° |

| 2 | Right Shoulder Roll | arm_r_joint2 | -190° ~ 10° |

| 3 | Right Shoulder Yaw | arm_r_joint3 | -180° ~ 180° |

| 4 | Right Elbow | arm_r_joint4 | -170° ~ 65° |

| 5 | Right Wrist Yaw | arm_r_joint5 | -180° ~ 180° |

| 6 | Right Wrist Pitch | arm_r_joint6 | -105° ~ 105° |

| 7 | Right Wrist Roll | arm_r_joint7 | -120° ~ 90° |

| 8 | Right Gripper | gripper_r_joint1 | 0 ~ 107.6 mm |

| 31 | Left Shoulder Pitch | arm_l_joint1 | -180° ~ 180° |

| 32 | Left Shoulder Roll | arm_l_joint2 | -10° ~ 190° |

| 33 | Left Shoulder Yaw | arm_l_joint3 | -180° ~ 180° |

| 34 | Left Elbow | arm_l_joint4 | -170° ~ 65° |

| 35 | Left Wrist Yaw | arm_l_joint5 | -180° ~ 180° |

| 36 | Left Wrist Pitch | arm_l_joint6 | -105° ~ 105° |

| 37 | Left Wrist Roll | arm_l_joint7 | -90° ~ 120° |

| 38 | Left Gripper | gripper_l_joint1 | 0 ~ 107.6 mm |

| 61 | Head Pitch | head_joint1 | -50° ~ 30° |

| 62 | Head Yaw | head_joint2 | -20° ~ 20° |

| 81 | Lift | lift_joint | 0 ~ 500 mm |

Mobile Base Configuration (Swerve Drive)

The AI Worker's mobile base uses a swerve drive system that provides significant advantages over traditional omnidirectional wheel systems like mecanum wheels or omni wheels:

Advantages Over Omniwheels and Mecanum Wheels:

Superior Traction: Swerve drive uses conventional wheels with full surface contact, providing better grip and stability compared to omniwheels and mecanum wheels that have smaller rollers with limited ground contact.

Higher Efficiency: Without the passive rollers found in omniwheels and mecanum wheels, swerve drive transfers power more efficiently to the ground, resulting in better energy usage and longer operation time.

Greater Precision: Swerve drive offers more precise control over movement direction and velocity, as each wheel's steering and drive are independently controlled with no slip dynamics inherent to roller-based wheels.

Improved Load Capacity: The direct wheel contact allows swerve drive to handle heavier loads more effectively, making it ideal for industrial applications where the robot needs to carry or manipulate objects.

Better Performance on Various Surfaces: While omniwheels and mecanum wheels struggle on uneven surfaces or soft carpets, swerve drive maintains consistent performance across different floor types.

Reduced Vibration: The continuous wheel contact with the ground produces less vibration during movement, which is critical for tasks requiring precise manipulation.

The AI Worker's swerve drive configuration consists of three wheels positioned in a triangular arrangement, each with independent steering and driving capabilities:

| Part Name | Technical Name | Range |

|---|---|---|

| Right Wheel Steer | right_wheel_steer | -90° ~ 90° |

| Left Wheel Steer | left_wheel_steer | -90° ~ 90° |

| Rear Wheel Steer | rear_wheel_steer | -90° ~ 90° |

| Right Wheel Drive | right_wheel_drive | -360° ~ 360° |

| Left Wheel Drive | left_wheel_drive | -360° ~ 360° |

| Rear Wheel Drive | rear_wheel_drive | -360° ~ 360° |

DYNAMIXEL Details

The AI Worker utilizes various DYNAMIXEL actuators, each selected for specific joint applications:

| Joints | DYNAMIXEL Series | DYNAMIXEL Model |

|---|---|---|

| Arm Joints 1~3 | DYNAMIXEL-Y | YM080-230-R099-RH |

| Arm Joints 4~6 | DYNAMIXEL-Y | YM070-210-R099-RH |

| Arm Joint 7 | DYNAMIXEL-P | PH42-020-S300-R |

| Gripper | Robot Hands | RH-P12-RN |

| Head Pitch | DYNAMIXEL-X | XH540-V150-R |

| Head Yaw | DYNAMIXEL-X | XH430-V210-R |

| Lift | DYNAMIXEL-Y | YM080-230-B001-RH |

| Wheel Steer | DYNAMIXEL-Y | YM070-210-R051-RH |

For detailed specifications of each DYNAMIXEL model, please visit the ROBOTIS DYNAMIXEL website.

Dimension

FFW-SG2

FFW-BG2

FFW-LG2

FFW-LH5

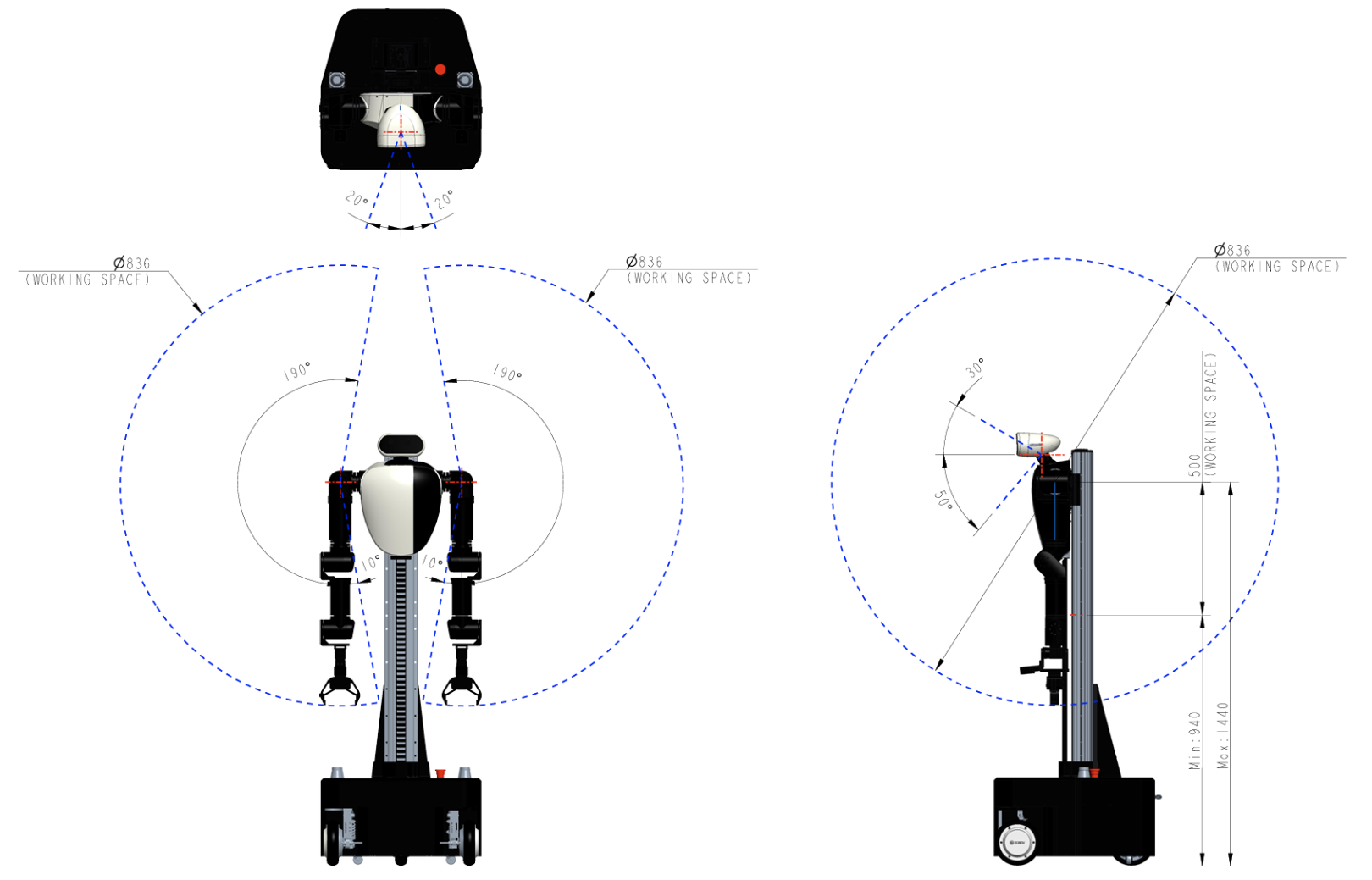

Workspace

The torso workspace is the same for both FFW-BG2 and FFW-SG2 models.